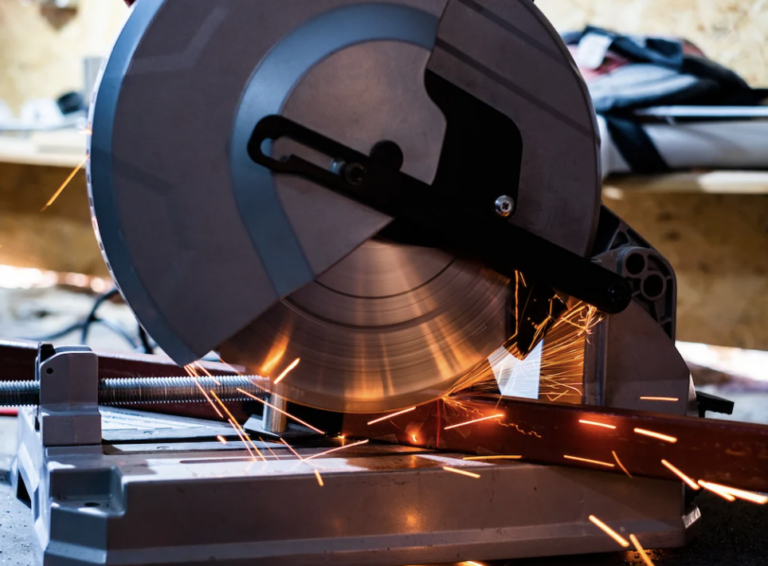

A miter saw for metal is an invaluable tool for various projects, as it enables precise miter cuts to match the angles you need for your cutting tasks. Models with higher levels of quality, such as motorized miter saws, offer the safest movement systems and an electric saw for faster material cutting. Keep reading to explore the various types of miter saws for metal available.

Best Miter Saw For Metal:

What is a miter saw for metal?

It is a tool that belongs to the saw family and is primarily used for cutting tasks. You can find more general tools like a miter saw for metal or more specialized ones designed for cutting specific types of alloys, such as a miter saw for aluminum.

The hallmark of these saws is their precision, which remains consistent regardless of your hand’s steadiness. This precision makes them essential for achieving perfect and fine finishes.

What are the parts of a miter saw for metal?

There are different models, but they all share some common elements:

Handle: It allows you to work safely and comfortably. Its mechanism enables you to raise and lower the cutting blade.

Arm release button: There is a button on the arm that you need to activate, in addition to squeezing the trigger on the handle, for the machine to operate.

Protective casing: The metal miter saw is protected by a fixed casing on its top and a mobile casing that opens as you cut the material.

Fence: Workpieces are supported against it to keep them securely in place before making a cut. Fences can be adjustable or fixed.

Cutting table: This is where the material is placed for cutting, allowing you to cut large pieces. The table’s capacity and the cutting capacity are directly related.

Cutting blade: The metal-cutting blade for the miter saw should match the saw’s diameter and be properly maintained for efficient operation.

Miter adjustment: This device is used to set the cutting angle for miter cuts.

Bevel adjustment: Almost all miter saws allow you to cut bevels at the same time as making miter cuts.

Chip extraction: This is an opening where you can attach a bag or a vacuum for removing chips or sawdust.

Support extensions: These are extremely useful for supporting longer workpieces. They are often removable depending on your needs.

Types of Metal Miter Saws

Depending on how they are used, metal miter saws can be classified as manual or motorized:

Motorized Miter Saws An electric motor powers the blade, allowing it to make cuts with minimal effort. These are the most common models on the market, and based on their technology, there are four main types:

Basic: This is the simplest model and allows you to work below the tool. It requires a snug fit for the workpiece you intend to cut.

Telescopic: These saws enable you to cut wider materials by extending their reach.

With Table: They come with a small table that allows you to work both above and below the tool.

Telescopic with Table: This type is ideal for precision work, such as cutting baseboards or moldings, as it combines the best features of the other models.

Manual Miter Saws This is the traditional model, preceding the popular motorized miter saws. They are now rarely found in the market and are only preferred by those who need a tool for small tasks and don’t want to make a significant investment. Manual miter saws work similarly to regular hand saws, but the addition of a base for securing the workpiece provides better precision and results than a regular hand saw.

Models for Working with Metal If you are considering buying a miter saw for metal, here are some highly-rated models recommended by users to help you make an informed decision:

Makita LH1200FL: This model boasts a power output of 1650 watts, can cut various materials, and provides high-quality angle cutting. While the initial investment may be relatively high, the results make it a worthwhile and satisfying investment.

Einhell TE-SM 2131: Another option for cutting various materials, it features a 1600-watt motor and offers good angle cutting capabilities. This miter saw is an excellent choice for working with metal.

Differences Between Metal and Wood Miter Saws

The primary difference between metal and wood miter saws lies in the cutting blade. Abrasive blades are used to cut metal, and they have a different shape and spindle than wood-cutting blades. Both types of saws should ensure the mechanism can be securely locked for safety, and a laser guide helps achieve accurate and straight cuts. A metal miter saw should have spark protection due to the sparks generated when cutting metal, while a wood miter saw may benefit from a dust collector.

For those who want to work with both wood and metal, it’s best to choose a miter saw that allows for the safe and precise cutting of both materials. Some models permit using the same blade for both purposes, while others allow for easy blade swapping.

Installing a metal-cutting blade on a wood miter saw is relatively simple, but it is essential to consider the size of the spindle and replace any necessary internal supports to ensure a proper fit.

Conclusion

to work with metal, it’s best to invest in a dedicated metal miter saw to ensure both safety and the longevity of the machine. While some tools are versatile, they are usually best suited for specific materials, as each model is designed with different calculations for power, motor speed, design, and materials.

Safety When Using a Metal Miter Saw Regardless of the type of miter saw you are using, it is essential to take some basic safety measures:

Wear basic protective gear such as safety glasses, masks, earplugs, and gloves to minimize dust exposure and protect yourself.

Wear suitable work clothing with tight sleeves and avoid wearing loose items like necklaces, bracelets, or watches to prevent potential entanglements.

Ensure your work surface is stable and well-lit.

Always unplug the machine when making adjustments to any part of the saw or the cutting blade.

Adjust the blade to match the material you intend to cut.

Do not remove the blade guards, as they are crucial for your safety.

In conclusion, we hope the information provided has been helpful in understanding the types and models of metal miter saws available, as well as the differences compared to wood miter saws. To use a metal miter saw properly, the best advice is to measure twice and cut once to make the most of your materials.